Company Introduction

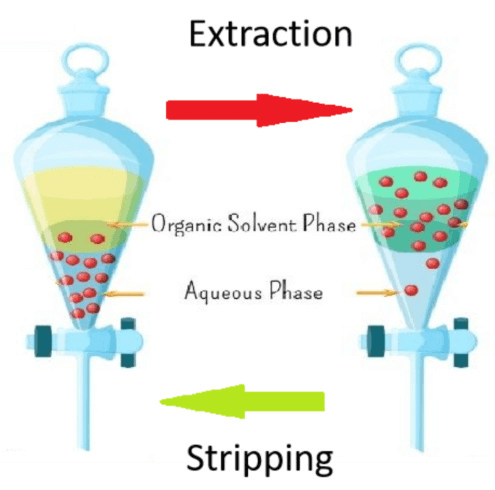

Zhengzhou Tiei Extraction Technology Co., Ltd has been deeply engaged in the industry of salt lake resource comprehensive utilization for many years. Relying on unique process technology and equipment, Tiei provides integrated solutions for salar or mining company including analysis and testing of brine, process R&D and verification, technology and technical service, lithium extraction equipment etc. After years of development, we have accumulated rich experience in lithium extraction from ores, natural brine, concentrated brine and lithium precipitation mother liquor etc. In order to better serve our customers,our process R&D team have developed the solvent extraction technologies that are more suitable for the comprehensive utilization of salar resources.